- International

- Argentina

- Australia

- Austria

- Belgium

- Brazil

- Canada

- China

- Czaech Republic

- Denmark

- Finland

- France

- Germany

- Hong Kong

- Hungary

- India

- Ireland

- Italy

- Japan

- Mexico

- Netherlands

- Norway

- Philippines

- Poland

- Portugal

- Republic of Korea

- Romania

- Russian Federation

- Singapore

- Slovenia

- South Africa

- Spain

- Sweden

- Thailand

- Turkey

- UAE

- United Kingdom

- United States

Safety Labeling Reduces Liability

Safety comes in many forms, but from a general perspective, accident prevention is where safety begins. And this is a critical point, especially when you consider that more workers died in 2019 than in any year since 1995.

If that’s not enough to raise eyebrows, last year, OSHA fines rose to $13,260 per violation, which is repeated for every day a company fails to correct the violation. Complying with ANSI and OSHA requirements makes “getting it right” all that much more important.

Today, there is a perception that electrical labeling is well established, that no new information affects what is already being implemented or enforced. Many inspectors and electricians, when confronted with the codes and the reason for the label requirements, are the first to admit they either do not label properly 100 percent of the time or are ignoring key code requirements. Facilities managers and companies manufacturing industrial automation equipment are sometimes lulled into a false sense of security when it comes to labeling equipment. This puts them and the companies they represent both financially and physically at risk.

Safety labeling needn’t be a mystery. Of course, it does help if your supplier can lend support in terms of verbiage, visuals and what labels are needed where. The design is more than a matter of word choice. It must comply with ANSI Z535.4, which defines the signal word text (Danger, Warning, Caution, Notice and Safety) along with the colors and newly required safety alert symbol. The old-style designs that did not include the safety alert symbol were made obsolete in 2002. However, they are still allowed for pre-existing installations that incorporated the old designs prior to 2002 to maintain consistency in the facility.

Once the format is selected, the safety manager must determine the level of hazard. Danger, for example, is reserved for situations that are likely to cause death or serious injury, while Caution is reserved for situations that could cause minor to moderate injury. That said, making this decision is somewhat subjective though critical. You are ultimately responsible for ensuring the equipment you manufacture, install or service has proper labeling. OSHA 29 U.S.C 654.5(a)1 states: “Each employer shall furnish to each of his employees employment and a place of employment which are free from recognized hazards that are causing or are likely to cause death or serious physical harm to his employees.”

Code compliance is made more complex considering all of the various sources of information that define proper and code compliant labeling. In addition to the newer National Electrical Codes, such as NEC 2017/2020, customers must also consider OSHA, ANSI and NFPA as well as UL for labeling requirements and specifications.

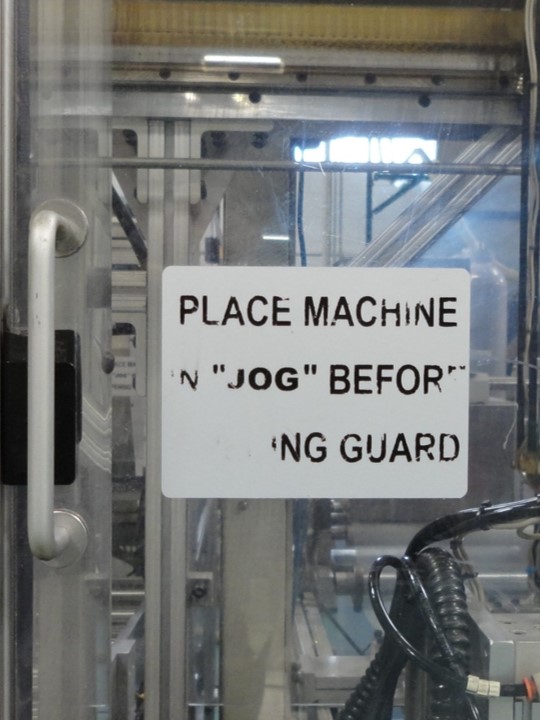

Given the seriousness of the issue, effectively communicating safety threats is only part of the challenge. Learning to recognize potential hazards in unique applications is yet another. When auditing your own facility, here are some things to consider for safety labeling:

- Are they consistent within the facility (new ANSI vs old ANSI)?

- Are they still legible (damaged or worn signs must be replaced)?

- Are they accurate and do they effectively communicate the message? It is important that the message be presented in either pictograms, text or both to ensure the operator understands the hazard immediately. Do they meet OSHA and ANSI standards? For example, is the signal word readable from a distance of five feet? Does the labeling need to be multilingual?

- Are existing signs affixed as close as possible to the hazard and not easy to remove?

Finding the right tools to help manage the constant changes, updates and new signage is a never-ending task. The responsibility of communicating hazards in and around the facility and particularly the equipment is a constant challenge.

It more than justifies the development of a continuous improvement program. When an internal auditor finally thinks your signage is up to date is often the last time anybody checks it for the next several years. This is what often leads to accidents, so maintaining a consistent policy on safety is critical.

Make safety as easy on your team as possible. Don’t rely solely on your own experience (or worse, beliefs), but instead, leverage the knowledge of the many experts at your disposal. Take advantage of any tools, procedures or tips that can augment your routine or challenge your own perceptions. If you are unsure, get a set of fresh eyes to review the situation. Failure to do so could end up tragically, and while OSHA does not accept excuses, none will relieve you of the financial and personal loss that could result from relying on inadequate or faulty assumptions.

Todd Fries is product category manager – identification systems for HellermannTyton North America. Todd has led the innovation of HellermannTyton’s identification products and programs for over 30 years, including a mobile labeling app designed to help installers remain code compliant. He has served on Code Making Panel 4 for NEC 2014, NEC 2017 and NEC 2020.

Good Labeling

Bad Labeling

Reprinted with permission from Solar Power World.

About HellermannTyton

HellermannTyton is a global leader in cable management and protection products, identification systems and network connectivity solutions. Its systems and solutions are specified by major manufacturers and contractors in the OEM, data communications, automotive, heavy equipment, renewable energy and related industries. The company’s engineered solutions and innovative products are designed and constructed to meet the strictest quality standards while delivering reliable implementation at the lowest cost. HellermannTyton operates in 39 countries, with North American headquarters in Milwaukee, Wisconsin. www.hellermann.tyton.com