Label My Equipment for Safety? I Don’t Have Time.

Label My Equipment for Safety? I Don’t Have Time.

By Todd Fries, marketing manager - identification systems

I know safety is important. I also know if I don’t label potentially hazardous equipment (or fix damaged labels), and someone gets hurt, OSHA will have a field day with my facility.

The problem is, like you, I just don’t have the time, which I know is a terrible thing to say.

What could be more important than worker safety? To be honest, nothing is more important. However, I get easily distracted and my well-intentioned plan to replace a damaged safety label or apply a new label gets lost in the daily grind.

If you are like me, you understand the problem and the risk. Even if you take the time to go online, research, design and order a needed label, it may take days or weeks to arrive, which means that the required warnings are missing.

This leaves the door open to possible injury and legal ramifications. What’s worse, the lag between ordering and receiving means you might forget where you wanted the sign and why it was needed. This is hardly efficient.

The simple things are never easy

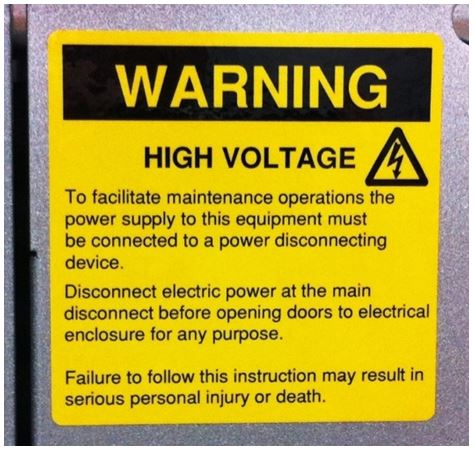

I look at a warning label and don’t think twice about it, until I realize that even though I have a label, I wonder if it is sufficient in communicating the danger. Take the following label as an example. How could it be more effective?

If I take the time to assess the risk, I might come up with several conclusions.

The HIGH VOLTAGE implies danger, yet this sign is a warning sign. If this can result in serious injury or death, the proper heading is “Danger,” not “Warning.”

Upon further research, I discover the ANSI recommends orange when using the “Warning” header. This label is yellow, which is reserved for the “Caution” header.

In addition, I’m supposed to use the “Safety Alert Symbol” in front of the word Warning.

If I take the time to assess the risk, I might come up with several conclusions

- The HIGH VOLTAGE implies danger, yet this sign is a warning sign. If this can result in serious injury or death, the proper heading is “Danger,” not “Warning.”

- Upon further research, I discover the ANSI recommends orange when using the “Warning” header. This label is yellow, which is reserved for the “Caution” header.

- In addition, I’m supposed to use the “Safety Alert Symbol” in front of the word Warning.

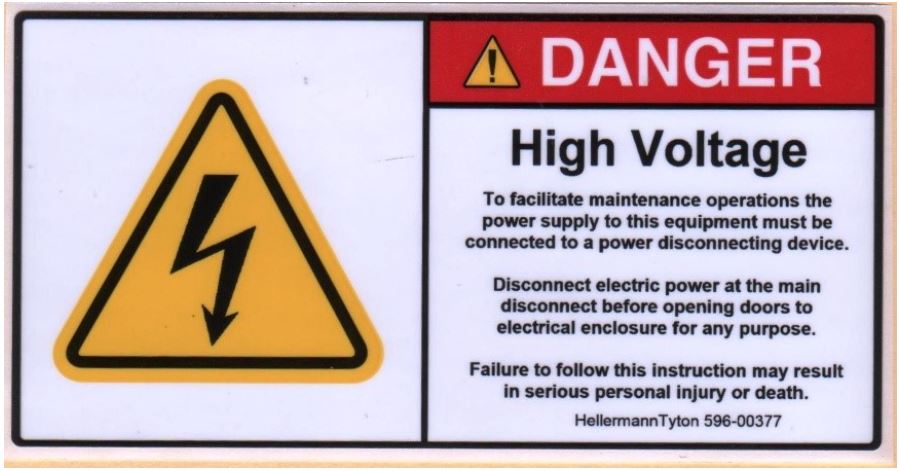

After a quick redesign, I can come up with a more effective and safe solution, which should reduce the risk of injury and the costs associated with it. However, this all takes time and special knowledge. What if I have neither?

What are my options?

The real me knows a thing or two about electrical safety standards. But the me in this story is more like the average label user. For most, becoming an expert on ANSI or OSHA labeling is probably not practical. Neither is hiring a consultant to review my current labeling. And if I try to do it myself, is it correct?

As for acquiring labels, ordering signs online used to be the best way to get things done. But there’s an expense involved with buying in small quantities and I may have a Minimum Order Quantity (MOQ). How many times have we needed only one of something but had to buy 10, only to file or scrap the rest? I can justify it as the cost of doing business, but is there a better way?

What to do?

There are several options to ensure a safe environment. I can hire a safety guru, whose main responsibility is to continuously audit and manage safety labeling. They can provide the expertise and drive internal safety programs as well as document and record safety efforts.

If hiring an expert isn’t in the budget, I can create a safety checklist or add audit reminders on my calendar. There are useful tools that can help, including safety audit apps. Typically, these apps are used for recording safety issues and generating reports, but generally don’t provide the safety solution. There are also sign making apps, but these apps don’t provide instructions on which type of sign is needed or how to design the best sign.

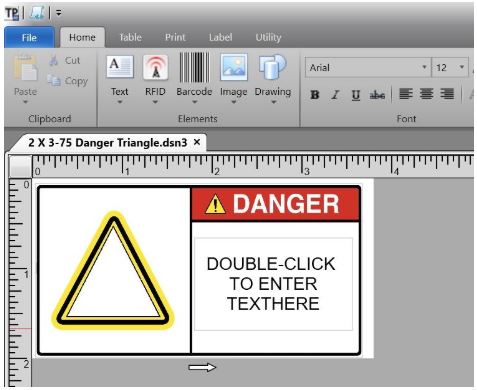

Figure 1: Visual and simple user interface with TagPrint Xpress Electrical

Most facility managers are usually out walking around when they spot a safety issue. In those situations, they can make a mental note to fix the problem or type a quick email to themselves as a reminder, but that doesn’t necessarily solve the issue and even with the best efforts, details are quickly forgotten during a busy day.

HellermannTyton has an app that lists the best warning types for a given safety issue and then helps the user design the sign, step-by-step until it is complete. The finished sign can be emailed to a team member for printing. Since I like to close out my to-do lists right away, and my smartphone is always on me, this solution makes a lot of sense for me.

Vendor Managed Inventory (VMI)

A distributor providing VMI services could purchase a printer and let me send label requests. Theoretically, I could get delivery the next day with my regular VMI shipment. Many Industrial printers incorporate resin-based inks that are durable and UV resistant. The materials used in the printer system should be pre-tested with various chemicals and solvents and even better, rated for outdoor use.

There are other ways to create signs. Many companies sell partially printed signs that already contain the pre-printed warning and even a space for text and images. Using label printing software and a thermal transfer printer, the black ink can print the pictogram (image) and the necessary safety language. The resulting label will be multi-colored and suitable for application in the facility.

Figure 2: Sign and label software, like TagPrint Pro, can load a pre-made design template. The user can add the text describing the danger and how to avoid it and then select an image to place within the triangle. Printed on quality label stock, the professional-looking sign will perform the job perfectly.

There are many shortcuts and tools available to help keep a safety program on track. They don’t have to be cost prohibitive if we select the right tools for the job. It’s all a matter of how we allocate our resources.

"Don't ignore OSHA sign requirements."

Have you ever had an OSHA investigated injury? Was lack of signage an issue? Could it have been prevented?

About the Author:

Todd Fries is HellermannTyton’s product category manager for identification. He has been involved with industrial identification since he started with the company in 1988. Todd is a voting member of NFPA Code Making Panel 4, NEC2014, 2017, 2020 and currently 2023. He is also a voting member of TIA-606-B standard committee, which defines the labeling of telecommunications infrastructure. Todd also participates on the SAE (Society of Automotive Engineers) technical committee for AE-8D wire and cable. His hobbies include competitive running, writing, playing music, restoring vintage radios and clocks and collecting old 78 rpm records.